Factory study

Objectives

-To help the manufacturers increase their productivity

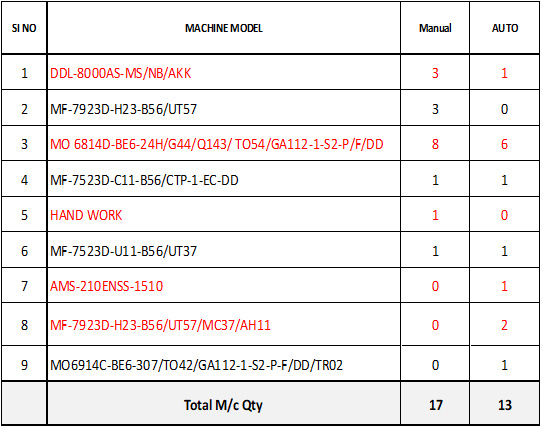

-To suggest appropriate machines for different operations

-To reduce unproductive time from sewing section

-To identify the bottlenecks in manufacturing sections and suggest procedures to streamline production.

-To suggest better machine layouts for minimal material handling.

-To suggest appropriate material handling systems

Benefits

Bottleneck areas can be identified for improvement.

-A better method of reforming of operation can be Suggested thus decrease the actual sewing time.

-higher productivity which leads to higher output and more Profits for the same number of machines

-Actual output / Actual efficiency can be determined

Contents

Phase 1- Operation rate research

Phase 2 3’iitie study and method study

Phase 3 Analysis of the observed data

Phase 4 Implementation

Period- 3 to 4 days depending upon design