What is Seam sealing & Bonding ?

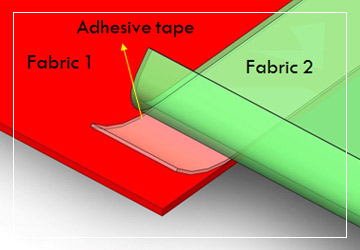

Seam sealing is a process of sealing up of the seam generally with a silicone coat or tape with a purpose of waterproofing the seam. But with the use of elastomeric adhesive tapes, this extra step of coating has been removed altogether and the tape gets fused directly onto the seam removing the need for stitch. Seam sealing can be defined as sealing of needle holes by applying adhesive tape with the help of hot air & roller presser.