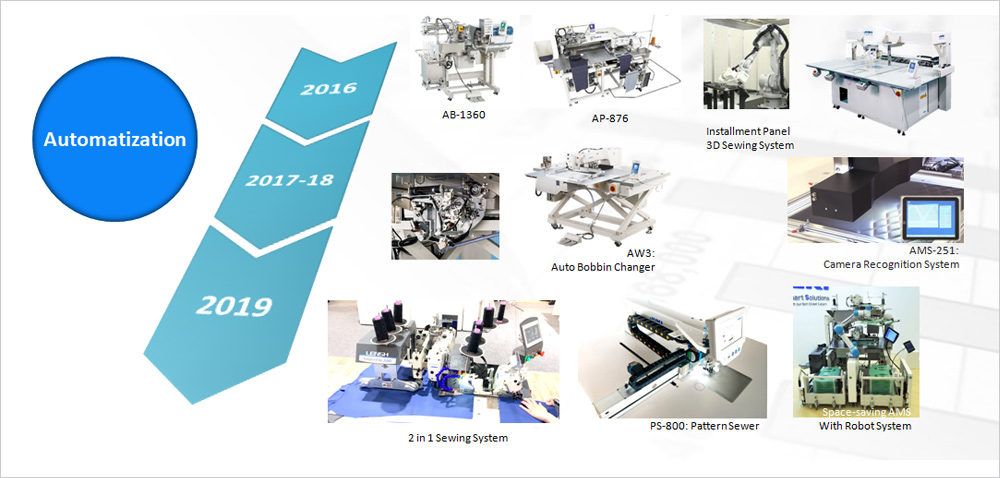

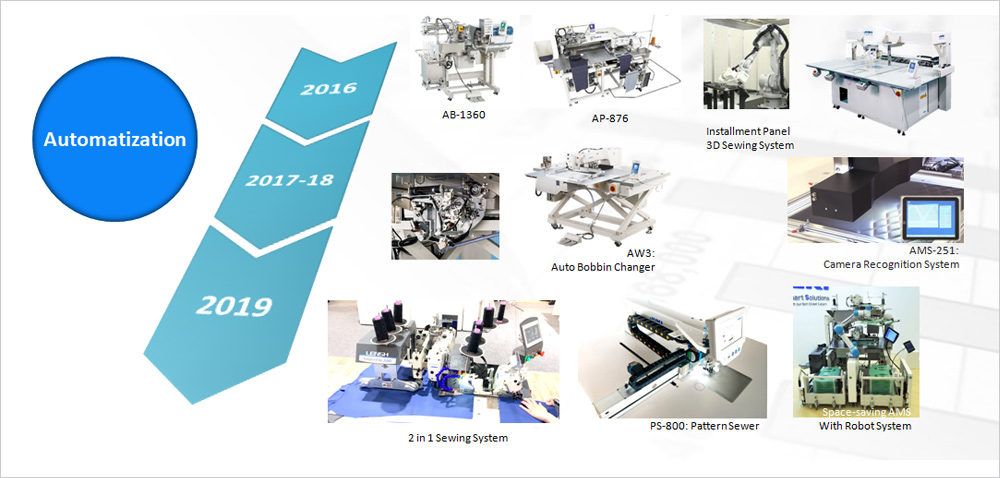

The following are the evolution of these concept in over period of time

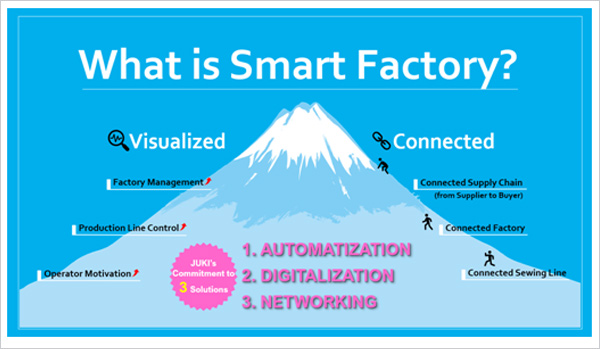

Due to the raise in global competition factories are required to reduce their manufacturing cost and to support them JUKI is coming up all new range of automatic machines which will help them process cost reduction.

Apart from cost reduction there are benefits like consistent quality and reduced rejection rate as there is no manual intervention. we have customers using all our automatic machines in Apparel, Knits as well as non-apparel.

Know More

JUKI’s Digital Sewing Machines can respond actively to changes in sewing items and materials. These sewing machines are capable of digitalizing “seam” adjustment functions and setting parameters can be stored as a pattern. The data after adjustment can be transferred through tablet or mobile with a dedicated app (application program) to other sewing machines.

» benefits Digital sewing concept

» Maximum machine setting will be done by panel .

» Quick change over of machine setting .

» Less line setting time

Know More

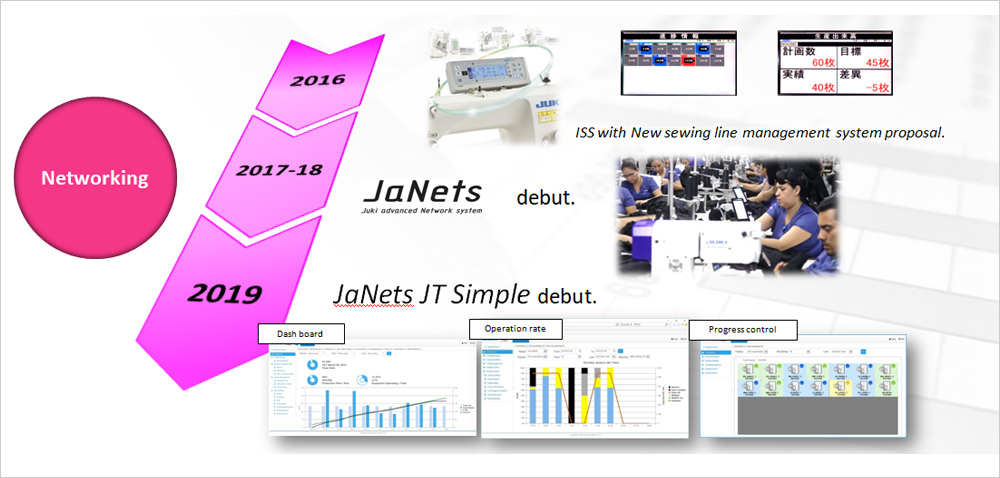

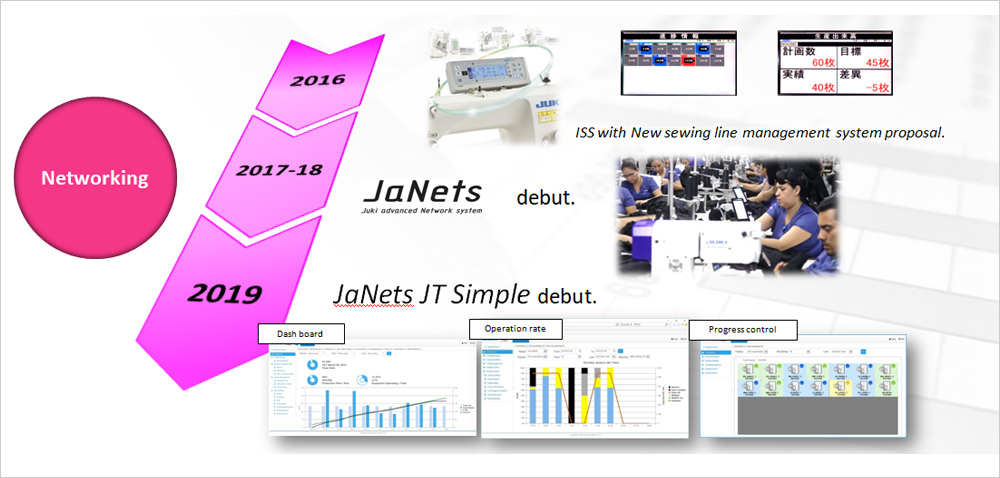

An IoT based system capable of performing connects all the machines in a network. JUKI meets customer demands by proposing line solutions to overcome production challenges using innovative, high-precision technologies under the “Smart Solutions” slogan.

Equipment data such as operation information on individual sewing machines is visualized in real time, analyzed and used for production improvements, speedy response and Operator education.

The real time data is important to take decision on time to avoid production delay due to communication gap between production helper to supervisor or IE . To reduce data collection all machines will be connected to Janet terminal from control box . All production and machine related information will be transferred to the panel. The same information is been transferred to cloud from Panel through WIFI based solution . All relevant information like production , machine operation rate and efficiency will be directly get updated in the server . So it makes seamless of information to available for all the related persons . Based on the real time date concern person can decision to avoid / solve the delay in production .

Benefits of Janets is as follows,

1 Real time data collection and production display on smiley based , easy to identify .

2 Problem points identification becomes easy .

3 It helps to increase production by 10 % minimum as it gives line balancing to be available in real time .

4 Machine utilization report will be available . It helps customer to make operator evaluation & training .

5 Maintenance call function to call maintenance person .

Know More